Welding Torch Weaver

Innovative welding techniques are used for better quality of weld and strong bonding of the two parts welded together. Weaving is one of them. However, uniformity and consistency are two important factors which are difficult to achieve manually. Orion Weaver Controller reliably provides a solution. Other variants with facility of online adjustments are also available.

Features :

- Very Precise Ball Screw and Rack & Pinion Mechanism.

- Well Protected from High Frequency Interference.

- Well Enclosed to avoid any Ingress of Fine Particles.

- Stepper Motor Controlled. Motor will be supplied along with the Machine.

- Entire Machine is Digitally Controlled. HMIs can be added along with the PLC unit.

- Easy Start and Stop Facility. Pulse ON mode or Stay-Put ON mode can both be Incorporated.

- Gives a Significant Improvement in Welding or Cladding Process.

- Strong Welding at joints is obtained.

Specifications :

- Traverse (Stroke Width) in mm

- Speed in mm/sec

- Start/Stop (Stepper Motor ON/OFF)

- Dwell Time A, Dwell Time B & Dwell Time C for Two Ends and Center

- Start Delay

- Forward/Reverse jog (Inching)

- Modes : Centre Stop ON/OFF

- Comes with built-in Stepper Motor Drive

- Power : Runs on 230VAC

- 320 X 265 X 110 mm din Enclosure.

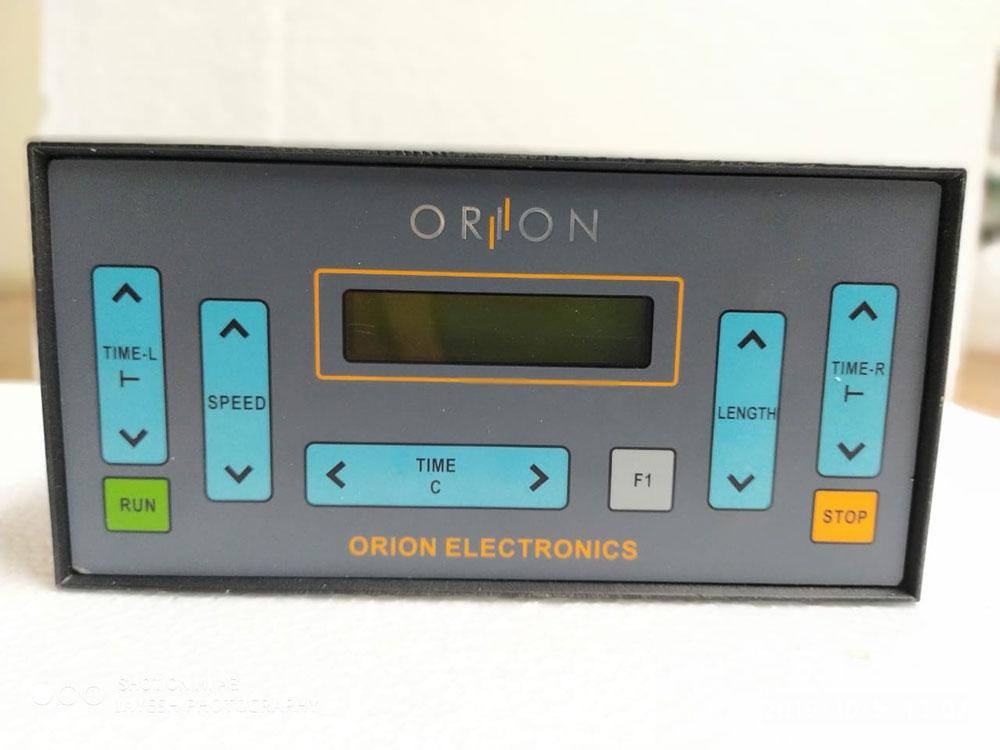

- 6 Key Membrane Keypad.

- 16 X 2 LCD Backlit Display.

- Provision for 2 Digital Inputs, 2 Relay Outputs.

- Customization Possible.

- Clock & Direction Signals to Stepper Drive for Weaving Action.

- Perfect Welding in Weaving Pattern is Obtained.

- Suitable for Low and High Frequency Welding.